Power transmission couplings – Universal Joints, jaw type couplings, beam couplings, bellows couplings and elastomeric couplings all suffer from the same design flaws.

Table of Contents

We have always used them, they are the only things we use, we just accept the annual maintenance cost and failure rate.

A common story from manufacturers and distributors, the power transmission coupling is the bottleneck of their equipment has always been either constantly maintenance or guaranteed failure or it can only be used a few degrees out of alignment so we are constantly stopping the equipment to make routine replacements of worn out components.

Lets look at the industrial distributor/manufacturers options when it comes to power transmission components.

Beam Couplings –

Whether single or multi beam , are very high speed but very low torque capable coupling, with the ability to flex to only 3 degrees makes them very limited in what they can be used for.

Their torsional stiffness (the coupling is a piece of metal with cuts made to allow it to flex) is quite high but this stiffness comes at the price of no flexibility, any machine wear because of changes of weight or angle of use means they wear quickly.

Made from a single piece of metal machined down to specification and then cuts are made in the sides, gives it the small misalignment angle

Bellows Couplings –

Like the Beam coupling, the Bellows coupling is almost identical in features and weaknesses. The Bellows can run at high speed but can only flex to 6 degrees, again making it another coupling that will wear quickly is any change to the angle of misalignment occurs, either intentional or not.

The same torsional stiffness as the Beam, the Bellows is a high speed coupling but with its low torque output and small size makes its use limited.

Jaw Coupling –

Jaw or L jaw or S Jaw couplings are different to beam couplings or bellows coupling as they are made up of 3 pieces, 2 hubs “jaws” and a polyurethane “hub or spider” in the center. While the Jaw coupling can also run at high speeds it can can only work at 2 degrees misalignment before the center hub starts to wear. The Jaw coupling can only handle small amounts of torque as well.

The L jaw coupling is what’s called a safety coupling, which means if the center hub fails the jaws clamp together and it can continue to function but without the hub to reduce vibration it will start to damage machinery components unless replaced.

There are another few Servo based coupling like the Oldham, Disc coupling and double loop but their design characteristics are the same as the couplings above, high speed but minimal flexibility and minimal torque.

The only other coupling used in automation is the universal joint.

Universal Joint –

The universal Joint is different to the servo couplings above in every way, it cant run at high speeds, it is more flexible than the servo couplings but because it uses bearings internally it has to be constantly maintained by greasing and has to be balanced or the joint becomes out of phase which leads to vibration.

The universal joint is also made of 3 components like the Jaw coupling, but instead of a membrane it has a “propeller” joint and at each point of the propeller it fits into the bearings.

So this means each universal joint contains 4 sets of bearings and these small bearings are seated in the Yokes or connections between each shaft, the bearing seats are small and a known failure point as they are so small.

The constant maintenance means is grease isn’t constantly fed into each of the bearings their constant use will mean the ball bearings will seize stopping the bearing from spinning and stopping the universal joint from working. Outside of that the ball bearings when the universal joint is used at an angle wear the side wall of the bearing race making the balls become loose leading to increased vibration and eventual cracking of the side wall.

These two traditional power transmission coupling units while useful have a hard time working in the 24/7/365 environment we now see with Amazon and other distribution systems.

The Twin Spring Coupling has the advantage of being a hybrid of both kinds of couplings.

The low angle high speed coupling Twin Spring coupling can accomplish that that Beam, Bellows, Jaw type coupling units, because the twin spring design contains an almost identical amount of force keeping the coupling from vibrating at high speed.

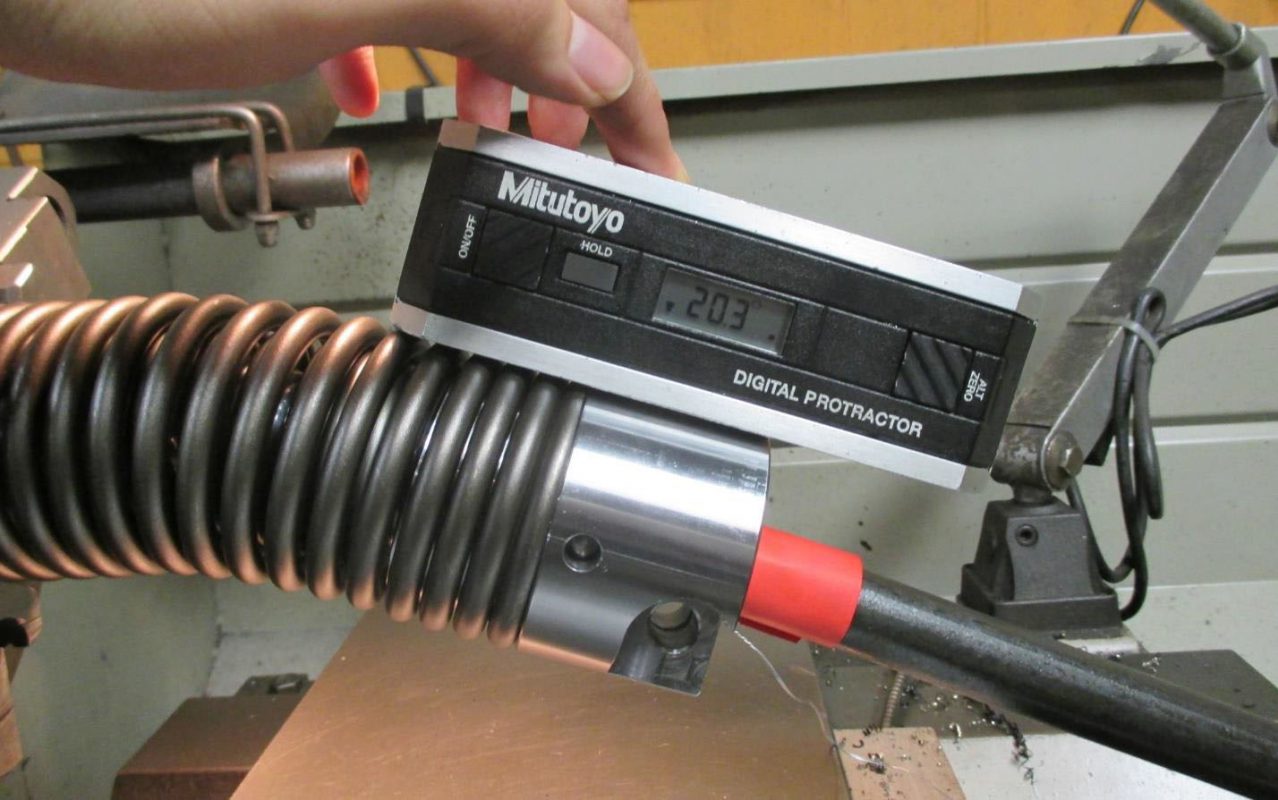

At a higher angle of misalignment but lower speed, identical to that of a universal joint made by Lovejoy or Spicer, the Twin Spring Coupling can flex due to its dual spring design but with only a central ball-bearing does not contain any internal bearings like that of a standard universal joint. These universal joint with the 2 yokes to connect the shafts means it like Jaw couplings are a three piece design, twin spring like a beam or bellows coupling is one piece.

Traditional power transmission couplings have their uses but in Industry 4.0 and modern day distribution systems their role has to be reconsidered when other solutions like the Twin Spring Coupling.

For more information on our product range and how they can resolve your power transmission coupling issues

Go to https://twinspringcoupling.com/products