Home of Premium Power Transmission Couplings for All Industries

DISCOVER premium power transmission couplings for automotive, INDUSTRIAL, mining, and agricultural applications.

High durability and fast shipping.

Featured Products

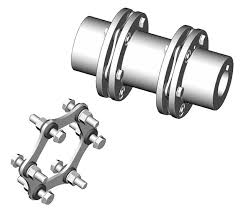

Couplings, Collars & Universal Joiners

$183.99

Agricultural couplings

$233.90

Agricultural couplings

$79.35

Automotive

$20.49

Agricultural couplings

$15.62

Agricultural couplings

$35.95