Replaces Universal joints, Beam coupling, Jaw coupling and spring couplings with one coupling

Twin Spring Coupling is the latest in flexible shaft coupling design

It can be used to replace high speed but low angle of misalignment couplings like beam couplings, jaw coupling and grid couplings, but are more flexible.

On the other end high angular misalignment but lower speed couplings like universal joints are able to handle higher amounts of torque but require constant maintenance, like greasing of bearings and replacing those bearings when worn..

Twin Spring Coupling as a flexible shaft coupling can do both.

Improving on existing flexible coupling technology we provide three different versions which allows a 0 to 45° operational angle of usage

-

- No internal components – Replaces the 4 bearings to be constantly lubricated and replace in a universal joint, this saves you time and money.

- Is designed for both parallel and angular misalignment

- One Piece design means no broken yokes or hubs.

- High speed- Runs at up to 7000 RPM

- Torsional rigidity at low angles of misalignment

- Different shaft types or sizes, from 1/2″ to 2 1/4″.

- Being made from two counter wound springs means it absorbs shock force without damaging equipment.

- Flexible up to 45° without the need to use internal ball bearings

- ISO9001 2007 manufactured

The patented twin spring design allows for larger angle of usage without deformation with the torque transfer seen with Universal Joints, giving the performance of a Universal joint without the constant maintenance.

So how it works compared to other couplings?

Universal Joints – U joints have 4 internal bearings or a block and pin design while flexible the pivot (block or bearing cross) needs lubrication otherwise the friction created due to use will cause bearing failure. The 3 piece design 2 yokes and bearing cross is replaced by our 1 piece integrated design, means less that can go wrong. With our coupling there are no internal bearings, so lubrication/maintenance becomes a scheduled semi annual event.

Jaw Coupling – Jaw type coupling either standard jaw couplings or curved jaw couplings, is a elastomeric coupling also called a Spider Jaw Coupling that again being a 3 piece design, two hubs and a insert or “spider”. Its job is to run at high speed but low angle of misalignment, anything outside of the 2° it starts to wear out the spider. The spiders job is also to absorb vibration. Our coupling with its twin torsion at low angles of misalignment it can run at the same high speeds, with higher torque and the same twin springs absorb vibration without the need for a insert.

Beam Coupling – Beam couplings are available in single beam or multi beam, the design is a simple one, a metal cylinder with cuts in the side of it, this allows a degree of flexibility all be it small, typically its less than 2° for the multi beam, 1° for single beam. These servo type coupling also have a low torque capacity. Our twin spring offers the same torsional rigidity but with increased flexibility. Like the our coupling it is also a one piece design.

Bellows Coupling – It also is a three piece design, two hubs and the bellows insert. It also has the same low angle of usage like that of the beam coupling, it runs at high speed but is only capable of low amounts of torque. We do the same but with increased torque.

Spring Coupling – The spring coupling has a design similar to the beam coupling. A one piece design with a spring and two hubs. It has a low torque capacity but can run at high speeds and can only work in a single direction and has a misalignment angle of 4°. Lovejoy Uniflex coupling is a good example of a spring coupling.

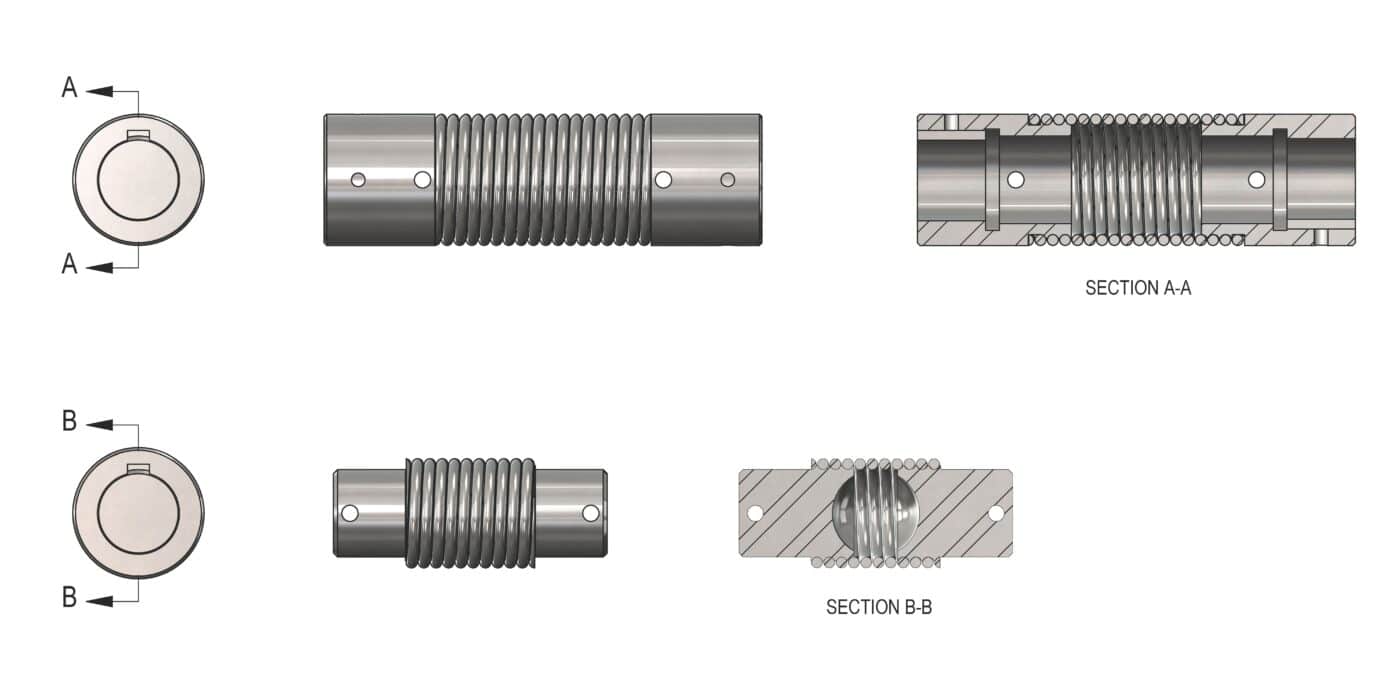

Twin Spring coupling’s design is quite simple and its simplicity is what makes it better for most coupling applications

The two torsion springs sets are used to allow power transfer in either direction, unlike spring couplings single spring design. The internal spring set has one central ball bearing, this allows for the transfer of torque from the input hub to the output hub and visa versa.

The twin torsion spring sets also have increased torque capacity over all other spring coupling types as the torsion spring is the strongest type of spring available. This also makes it comparable to the torque output of the common universal joints, whether the block and pin or needle bearing type.

The internal assembly is inserted into the outer assembly and shear pins are installed at either end, locking the two spring sets together. This also serves a second purpose of being a built in safety mechanism to stop excessive torque being transferred. This serves to protect equipment attached to the coupling from damage. The coupling can be reset with the replacement of the shear pin to resume operation without replacement of the whole coupling.

Coupling technology hasn’t changed until now.

Its time for something new, simple and one coupling can replace most other commonly available coupling systems, whether Lovejoy, Spicerparts, Ruland, TB Woods Uni joint, Jaw couplings, servo couplings or beam couplings.

One coupling – multiple coupling solutions

Click on the industries below to see how our couplings will help you