Weasler PTO couplings

Table of Contents

Weasler PTO couplings are a brand well known in the agriculture u-joints, Walterscheid and Bondioli as well . They all rely on the underlying universal joint technology to work.

The only real difference is the Weasler PTO couplings are made using larger uni joints, revolving around technology like the Spicer 1310/ Spicer 5-3213X universal joint models.

To add to this the bearing cross or the universal bearings need to be greased either every 8 or 50 hours of use to ensure they don’t seize through the bearings using the grease up to lubricate and keep the ball bearings cool, the lack of grease means the ball bearings expand and wear the bearing race. The amount of constant work the universal joints are put through without greasing regularly will guarantee bearing failure.

While farming universal crosses are cheap and relatively easy to obtain, the time and effort to have to obtain them, and the time and lost earnings through having to pull the coupling apart and replace the cross makes a cheap coupling not so cheap.

These worn bearings are also caused by the angle of misalignment that the Weasler couplings are used at, PTO based attachments can be used at all kinds of angles due to the irregularity of the land and kind of attachment used, turning circles (for larger equipment like mowers, rotary tillers etc)

The constant up and down side to side movement means the bearings are forced against the sides of the bearing race making them wider, eventually the race becomes so wide the ball bearings can come loose. This wear is documented in the coupling manufacturers web site and dictates how often the bearing cross has to be replaced.

This means constant maintenance and replacement of these bearing wear parts.

Outside of that is the actual input and output yokes, the coupling connections between the PTO shaft and the equipment. PTO Yokes hold the bearing cross in place, these are cast iron connections in either a 6T, 20T or 21T tooth input configuration and a shaft with keyway or shaft with a clamp on the output end.

These yokes have a life span much like the universal bearings but a crack or split in these yokes is more likely the cause for them to be replaced, which means disassembly of the PTO coupling, buying a replacement PTO Yoke and reassembly.

How are Twin Spring Couplings better?

The Twin Spring coupling agriculture range is broken into two models and can be used from Category 1 through to Category 4 PTO Hitch systems

The TSC300 this model is capable of handling 300 ft lbs. or 3600 in lbs of static torque

The TSC500 this model is capable of handling 500 ft lbs. or 6000 in lbs. of static torque.

The TSC300 model is the equivalent of the following Weasler PTO couplings

12 series – 200-1200

6 series – 200-0600

AB2/AW20 – 200-8261

AB1 – 200-6154

0675 – 200-0675

AW10 – 200-7155

1000 series – 200-1000

1FR series – 200-0100

The TSC500 model is the equivalent to the following Weasler PTO couplings

35 series – 200-3500, 200-3501 and 200-7676

AB4/AW21 – 200-8474

AB5 – 200-6580

AW21-80 – 200-7491

Input/Output Yoke replacements

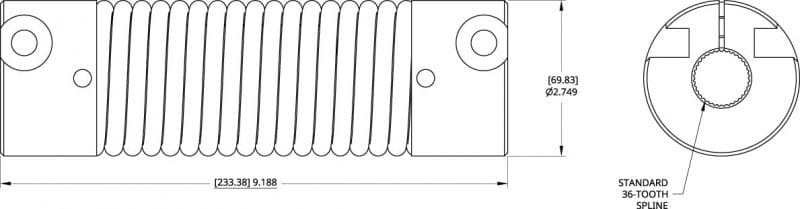

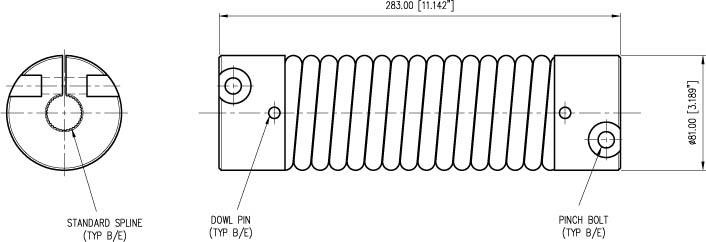

As Twin Spring Couplings are an all in one design the standard PTO input and output yokes are replaced and are available in 6T, 20T, 21T PTO configurations as well as 1/2″ (13mm) to 1 3/4″ (45mm) shaft with keyway as well.

The real difference

The main difference between Weasler PTO couplings universal joints and Twin Spring Coupling is the Twin Spring Coupling doesn’t have any bearings so there is no constant greasing, no constant replacing of the bearing crosses when they wear out.

Twin Spring uses one central ball bearing which means a semi annual greasing and that’s it, no bearing cross to replace. Add to that the one piece design means no yokes to break and needing to be replaced.

Another safety feature of the Twin Spring Coupling is the built in shear pins, this means that if the equipment has issues, the shear pins act as a safety device to save the equipment from damage.

Integrated coupling unit

A one piece coupling with the Z6, Z20, Z21 input and your option of output dependent on your equipment needs. This one piece design means the coupling lasts a lot longer, with money saving in a number of areas, Maintaining the coupling – no greasing, no replacing components.

Both failed and preventative (bearing cross, yokes) labor to keep the couplings working and the loss of earnings when the couplings are not in service.

So how does the Twin Spring coupling compare in regards to performance to universal joints in the Weasler PTO couplings.

Twin Springs simple design of 2 torsion springs means the coupling is as flexible as a universal joint rotating around the central ball bearing, this spring coupling means its flexible on turns and the up and down and side to side action that wears away at a uni joint but when back to a straight line means it goes back to the high speed coupling it was designed to be.

With no bearings to dissipate the generated heat, which means the Twin Spring coupling can run for longer, faster without the worry of the constant use destroying the coupling as it would with a universal joint.

Price

So with all this, its the same price as what you would pay for a high end product like the Weasler, its 3 seperate components rather than our 1 piece means its something that can be made cheaper. With a better return on investment it means that you should add Twin Spring Coupling to your list for replacements for your Weasler PTO couplings

Not just PTO

Our agriculture u-joint couplings can be used with all forms of equipment, not just PTO based attachments, our couplings can also be used to replace jaw couplings and uni joints inside equipment, on pumps, anywhere a power transmission coupling is used, we can probably replace it.

Jaw couplings are also common inside agricultural equipment as its a safety coupling, which unlike a universal joint if the spider insert of a jaw coupling fails the two input and pot yokes cramp together to keep the piece of equipment running but with a large increase of vibration which can damage the piece of equipment.

As the Twin Spring coupling is a one piece design it can also be considered a safety coupling as it wont break apart.

For more information on our range of Agricultural couplings please visit

https://twinspringcoupling.com/industries/agriculture/