Bearing Failure in Uni joints, there are only a few option available. The universal joint is one of these fundamental shaft coupling solutions, it’s been used for the past 115 years in the automotive industry and longer in other areas like Industrial and farming. The three-piece design while simple, has always had to been maintained […]

Tag Archives: Lovejoy universal joints

Lovejoy universal joints are in 2 model types the old block and pin and the newer needle bearing models.

Both still need their center maintained (block constantly greased like the needle bearing) and replaced when worn. The block and pin design can only be used at 1750 RPM and NB model 6000 RPM.

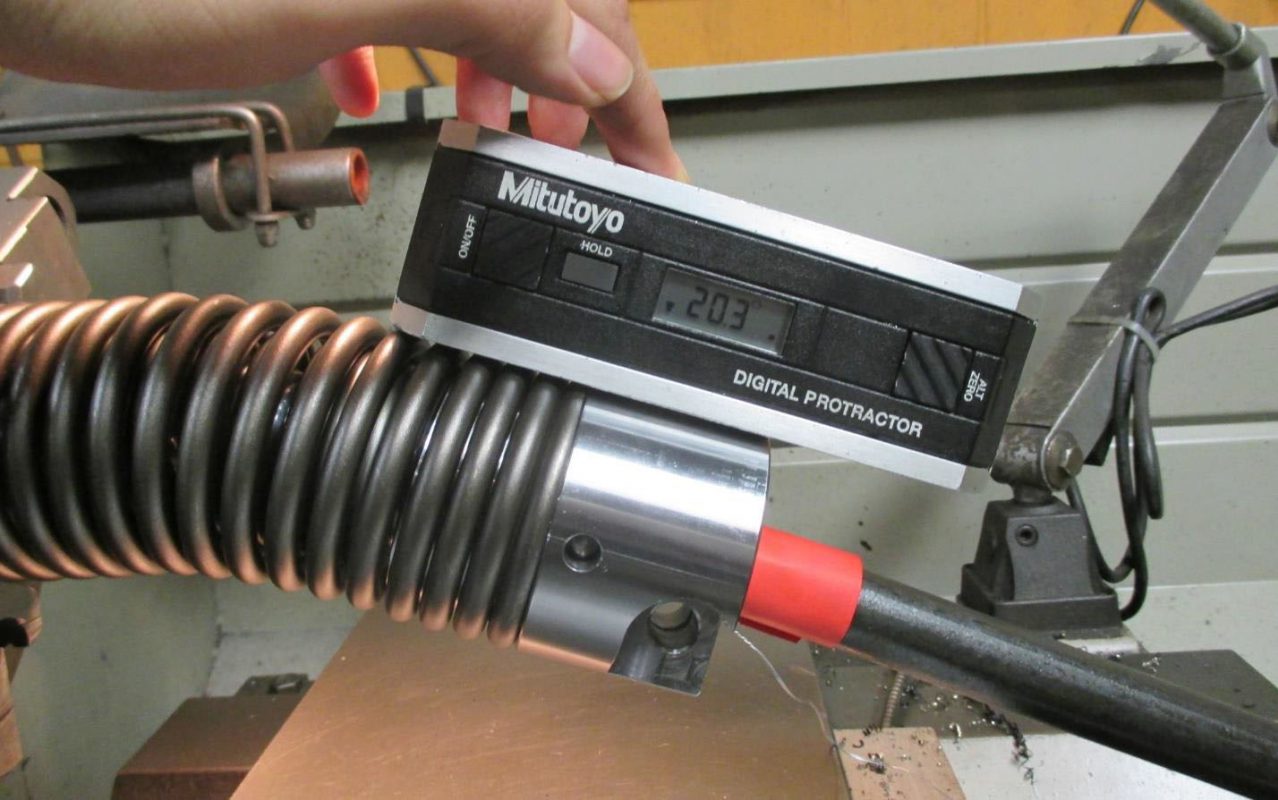

Twin Spring Coupling can run at 7000 rpm, more flexible (up to 45° angular misalignment) and high torque (Up to 6000 In Lbs. of static torque)

One TSC coupling can replace both Lovejoy universal joints.

Coupling solutions replace Lovejoy Universal Joints, Jaw couplings and other couplings. With the 24/7 demands on industrial couplings especially now with the COVID 19 virus meaning less service people and OEM MRO supplies are available, the service manager of these industrial companies have decisions to make. How do I get the most out of the […]

The true cost of universal joints are not so simple, a low initial price but with ongoing maintenance means it becomes a lot more expensive Lets face it, its an old technology, 115 years old to be exact, the first use of the word by inventor Robert Hooke in 1676 shows the coupling is far […]

Spring’s here – its universal joint maintenance time. Universal Joint and power transmission couplings So the weather is changing, the short cold days of winter are starting to recede. Now is the time of the service manager starting to his maintenance schedule for plant and equipment. Couplings come into play here as the constant greasing […]

Power transmission couplings – Universal Joints, jaw type couplings, beam couplings, bellows couplings and elastomeric couplings all suffer from the same design flaws. We have always used them, they are the only things we use, we just accept the annual maintenance cost and failure rate. A common story from manufacturers and distributors, the power transmission […]

- 1

- 2