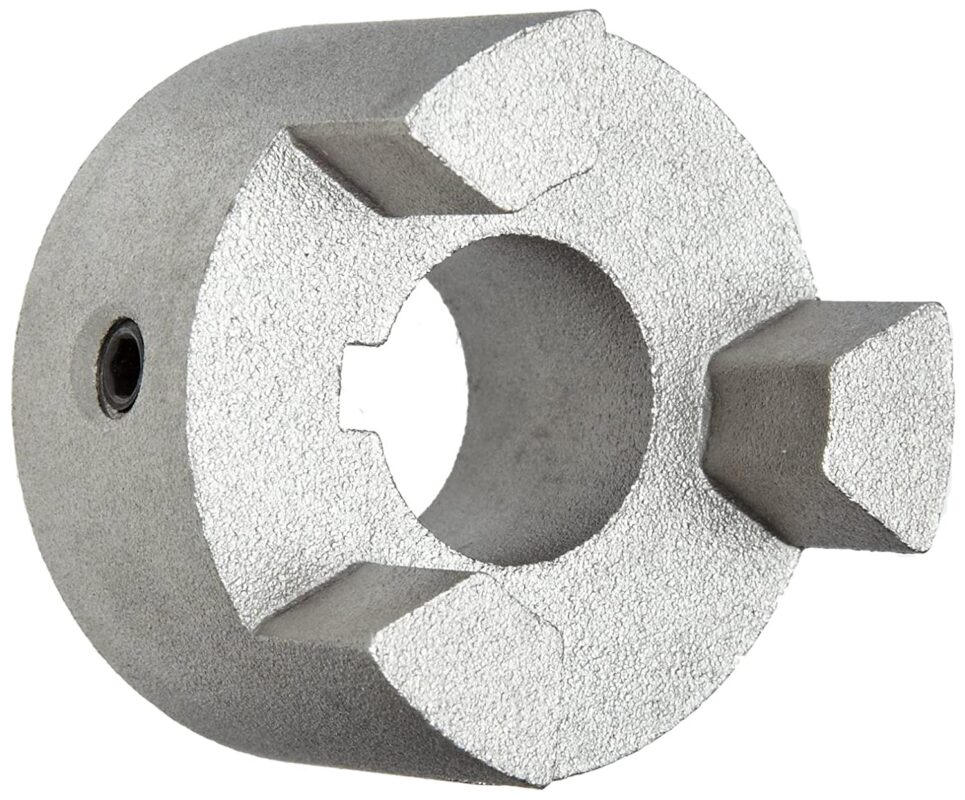

Martin MS190 13/16 Super Series Jaw Coupling hub

MS190 1 13/16

UPC: 697950133157

Martin Offers Two Complete Lines of Jaw Couplings, One for Greater Horsepower and One for Interchangeability. Features include: no lubrication, easy installation, no metal to metal contact resistant to oil, dirt, sand, moisture, grease, easy inspection of load carrying spider, flexibility of angular or parallel misalignment of shafts by Buna-N Spider member permits smooth “Power Transmission”. Buna Rubber, Hytrel and Urethane Spiders are stocked in all branches.

Material Steel

Coupling Size 190

Outside Diameter 4.5000 in.

Length Thru Bore 1.9375 in.

Bore Type Finished Bore

Finished Bore Size 1.8125 in.

Key Way Size 1/2 X 1/4 in.

Set Screw Size 1/2-13 unc in.

Set Screw Location (1) Set Screw Over Keyway

Number of Set Screws 1

Min Bore Size 1.8125 in.

Max Bore Size 2.1250 in.