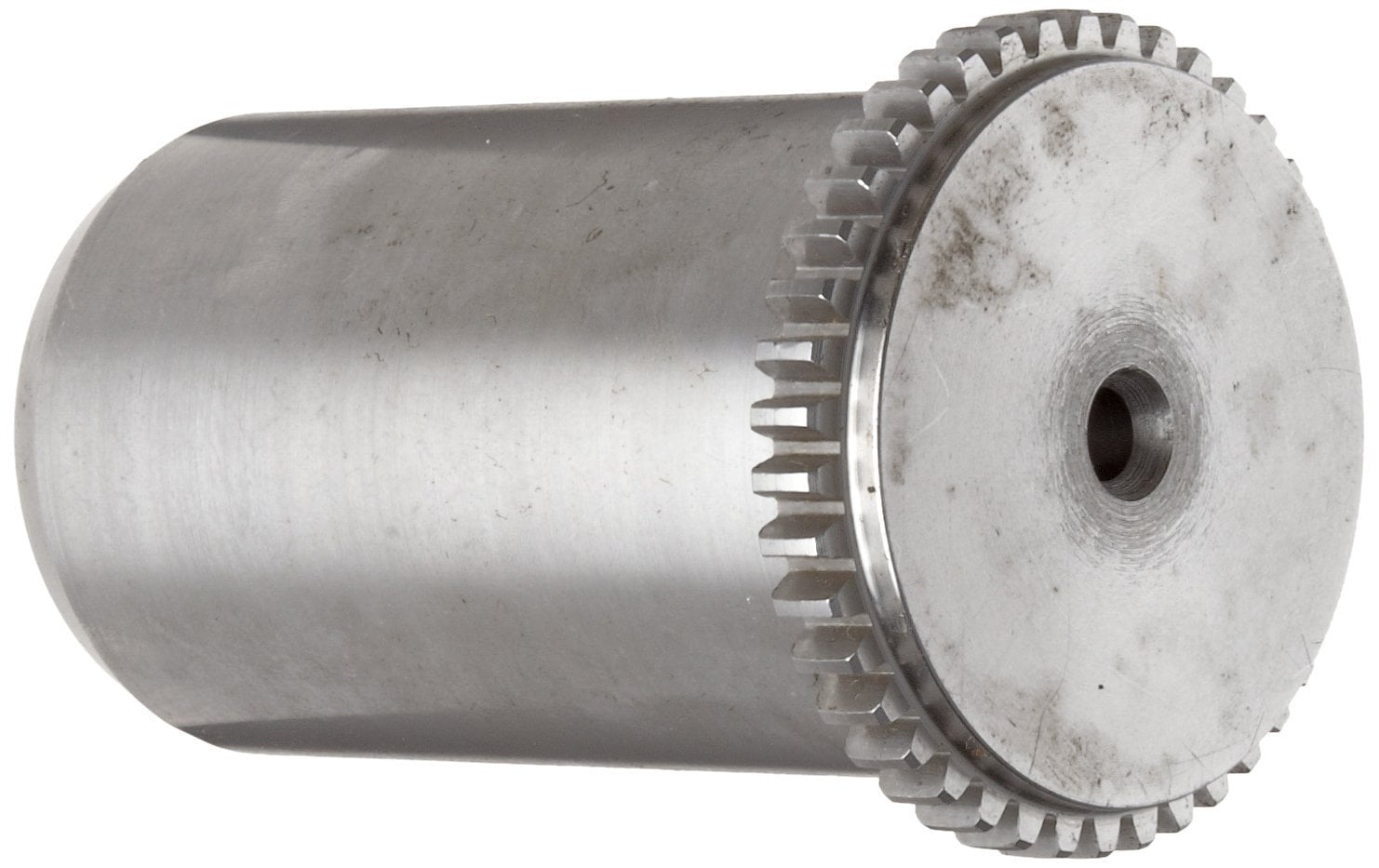

Lovejoy CMM 2.5 HUB 2.375/2.376 5/8KW

Lovejoy 69790411709 CMM 2.5 Sier-Bath Continuous Sleeve Gear Coupling, Flex Hub, Steel, Inch, 2.375/2.376″ Bore, 5.50″ Coupling OD, 3750 Maximum Unbalanced RPM, 30200 in-lbs Nominal Torque, 0.625″ x 0.3125″ Keyway

Dimensional Data

Bore Size | 2 3/8 in |

Size | 2 1/2 |

Keyway Size (W x D) | 5/8 in |

Overall Length | Determined by Length of Mill Motor Hub |

Max. Bore (Dimensions ID1/ID2) | 2.630 in 70.00 mm |

Outside Diameter | 5.500 in 5.50 mm |

Dimension CBD | 3.750 in 95.25 mm |

Max. Safe Counterbore (Dimension CBD1) | 3.250 in 82.55 mm |

Dimension DC | 0.250 in 6.35 mm |

Dimension DC1 | Determined by Customer Specifications |

Dimension G | 0.250 in 6.35 mm |

Max. Length of Universal Hub (Dimension HL1) | 5.130 in 130.30 mm |

Dimension HD | 3.94 in 100.08 mm |

Dimension HL | 2.250 in 57.15 mm |

Dimension LS | 3.060 in 77.72 mm |

Dimension R | 5.720 in 145.29 mm |

Dimension SL | 1.530 in 38.86 mm |

Cubic inches | 34.92810 in³ |

Performance Data

Nominal Torque | 30200.00 in·lb |

Max. Speed (Unbalanced) | 3750.00 rpm |

Max. Angular Misalignment | 0.50 º |

Parallel Misalignment | 0.007 in |

Features

Features |

|

Notes

Notes |

|

Lovejoy CMM 2.5 HUB 2.375/2.376 5/8KW

Industrial Couplings

This Lovejoy CMM Type flex hub is made of steel and is intended for use as a component of a Sier-Bath continuous sleeve gear coupling (not included). This hub is specifically designed for mill motors with tapered bores and is made of American Iron and Steel Institute (AISI) 1045 steel for strength and durability. The hub teeth are fully crowned for larger contact area with the sleeve teeth and lower stress under misaligned conditions, which allows for angular misalignment of up to 0.5 degrees per hub. The hub also accommodates parallel and axial misalignment of the attached shafts. Gear couplings, a type of flexible coupling, use gear teeth on hubs and sleeves to transmit torque and offset rotational misalignment, and are suitable for use in applications involving extended distances between shaft ends, such as metal rolling mills and paper mills.Flexible couplings are used to link two rotating shafts that are not aligned in order to transmit the rotational power, known as torque, from one shaft to the other. Most flexible couplings consist of two hubs and a middle assembly; each hub attaches to a shaft while the middle assembly flexes between the hubs to accommodate the misalignment of the two shafts. Shaft misalignments are generally either parallel or angular and cause complications to transmitting rotational power from one shaft to another in the form of stresses, loads, vibrations, and other forces, which vary from one type of misalignment to another. Flexible couplings are used in a broad range of applications, such as in motor vehicles, conveyors, escalators, agricultural, forestry and mining equipment, aeronautics, robotics and space exploration, among others.Lovejoy manufactures flexible couplings, universal joints, variable speed drives, and other transmission and mechanical power products. The company, founded in 1900, is headquartered in Downers Grove, IL.