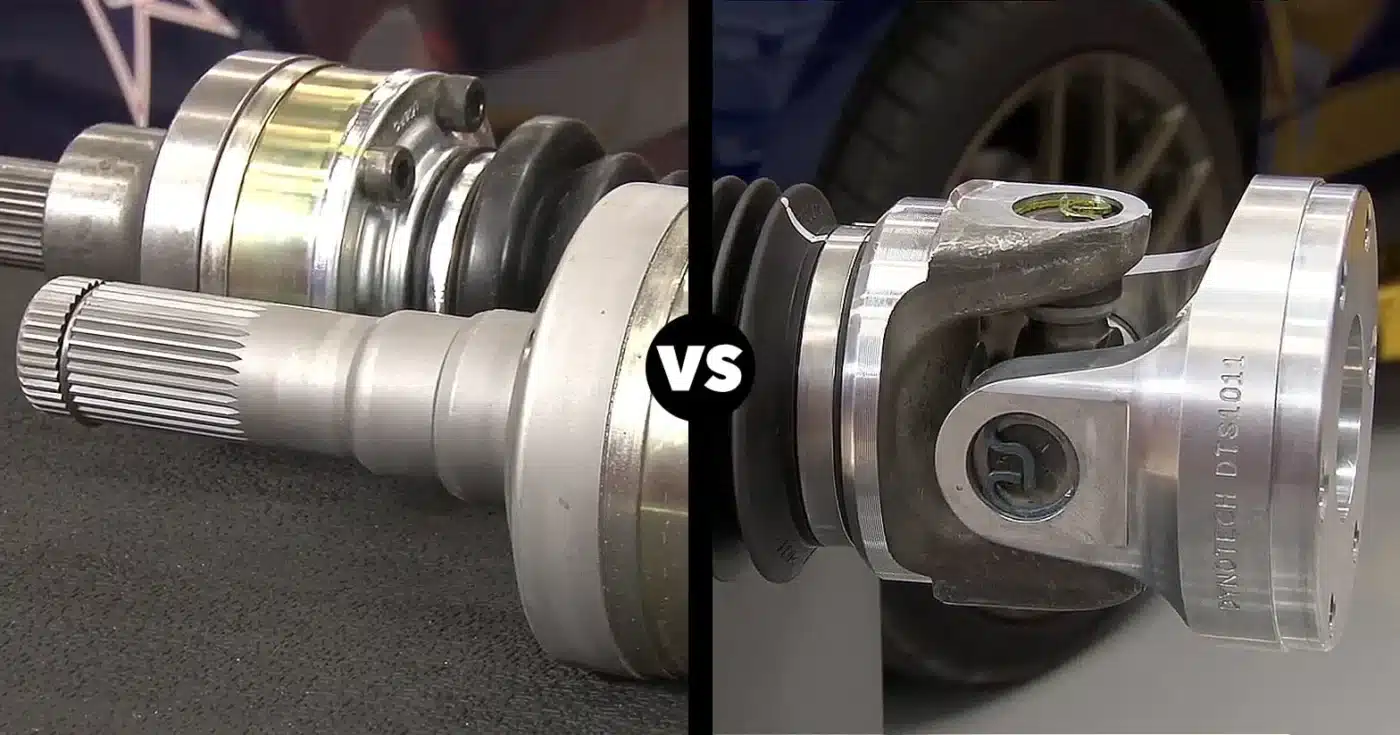

Universal Joints vs. Constant Velocity (CV) Joints – A Comprehensive Comparison.

Table of Contents

In the world of automotive engineering, the transmission of power from the engine to the wheels is a critical aspect of vehicle performance. Two key components that play a vital role in this process are universal joints (U-joints) and constant velocity (CV) joints.

While both serve the purpose of transmitting rotational power, they have distinct characteristics, advantages, and applications. This comprehensive comparison will delve into the intricacies of these two joint types, exploring their design, functionality, pros and cons, and specific use cases.

– Understanding Universal Joints.

Universal joints, also known as U-joints or Cardan joints, have been a staple in automotive drivetrains for decades. These mechanical couplings allow two shafts to transmit rotational power while operating at an angle to each other.

– Design and Functionality.

A typical U-joint consists of a cross-shaped component (called a spider) with four protruding trunnions. These trunnions fit into yokes at the end of each shaft, allowing for flexible rotation. The design enables the joint to accommodate changes in angle between the shafts while continuing to transmit torque.

– Applications.

U-joints are commonly found in:

1. Rear-wheel-drive vehicles.

2. Four-wheel-drive vehicles.

3. Heavy-duty trucks and industrial machinery.

4. Agricultural equipment.

– Advantages of Universal Joints.

1. Robustness: U-joints are known for their durability, making them suitable for heavy-duty applications[1].

2. Cost-effectiveness: Generally less expensive than CV joints, both in terms of initial cost and replacement[1].

3. Simplicity: The straightforward design makes U-joints easier to maintain and repair[1].

4. Wide angle capability: Can operate effectively at more extreme angles compared to some CV joints.

– Limitations of Universal Joints.

1. Non-constant velocity: U-joints do not maintain a constant rotational speed throughout their rotation, which can lead to vibrations and wear over time[1].

2. Angle restrictions: While they can handle wide angles, extreme angles can cause binding and increased wear.

3. Potential for vibration: At high angles or speeds, U-joints can introduce vibrations into the driveline[1].

– Exploring Constant Velocity (CV) Joints.

Constant velocity joints, as the name suggests, are designed to maintain a constant rotational speed even when operating at an angle. This characteristic makes them particularly valuable in modern vehicle designs, especially those with independent suspension systems. They are manufactured by companies like Dana Spicer and Neapco.

– Design and Functionality.

CV joints come in various designs, but the most common types are:

1. Rzeppa joints: Featuring six balls guided by an inner and outer race, these joints are often used on the outer end of drive shafts.

2. Tripod joints: Using three trunnions instead of balls, these are typically found on the inner end of drive shafts.

The design of CV joints allows them to distribute force evenly, maintaining constant velocity throughout their rotation.

– Applications.

CV joints are predominantly used in:

1. Front-wheel-drive vehicles.

2. All-wheel-drive vehicles.

3. Independent suspension systems.

4. Steering columns.

Advantages of CV Joints.

1. Smooth power transfer: CV joints maintain constant velocity, ensuring smooth power delivery even at varying angles[1].

2. Reduced vibration: The constant velocity characteristic minimizes driveline vibrations[1].

3. Improved efficiency: By maintaining constant velocity, CV joints are more efficient in power transmission.

4. Better performance in varying conditions: Ideal for applications where joint angles change frequently, such as in steering systems and independent suspensions.

Limitations of CV Joints.

1. Maintenance requirements: CV joints typically require more frequent inspection and maintenance, particularly of their protective boots[1].

2. Cost: Generally more expensive than U-joints, both for initial installation and replacement[1].

3. Complexity: The more intricate design of CV joints can make repairs more challenging and time-consuming.

Comparative Analysis.

To better understand the differences between U-joints and CV joints, let’s compare them across several key factors:

1. Velocity Consistency.

U-joints: Do not maintain constant velocity during rotation, which can lead to speed fluctuations and potential vibrations.

CV joints: Designed to maintain constant velocity throughout their rotation, ensuring smooth power transfer.

2. Angle of Operation.

U-joints: Can operate at wider angles but may introduce vibrations and wear at extreme angles.

CV joints: Generally operate smoothly at angles up to about 45 degrees, making them ideal for steering and suspension applications.

3. Durability and Maintenance.

U-joints: Generally more robust and require less maintenance. They can often be serviced or replaced without removing the entire driveshaft[1].

CV joints: While durable, they require more frequent inspection, particularly of their protective boots. Damage to the boot can lead to premature failure of the joint[1].

.

4. Cost Considerations.

U-joints: Typically less expensive, both for initial installation and replacement[1].

CV joints: Generally more costly, which can impact both vehicle design and maintenance expenses[1].

5. Vehicle Applications.

U-joints: Commonly used in rear-wheel-drive, four-wheel-drive, and heavy-duty vehicles where their robustness and ability to handle high torque are advantageous[1].

CV joints: Predominant in front-wheel-drive and all-wheel-drive vehicles, where their smooth operation and ability to handle varying angles are crucial[1].

6. Performance in Extreme Conditions.

U-joints: Better suited for heavy-duty applications and can handle higher torque loads.

CV joints: Excel in applications requiring smooth power transfer at varying angles, such as in off-road vehicles or those with complex suspension systems.

– Choosing Between U-joints and CV Joints.

The choice between U-joints and CV joints often depends on the specific application and vehicle design. Here are some factors to consider:

1. Vehicle drivetrain: Front-wheel-drive and many all-wheel-drive vehicles typically use CV joints, while rear-wheel-drive and some four-wheel-drive vehicles often employ U-joints.

2. Suspension design: Vehicles with independent suspension systems generally benefit from CV joints due to their ability to handle varying angles smoothly.

3. Performance requirements: For applications requiring smooth power transfer and minimal vibration, CV joints are usually preferred.

4. Cost considerations: In budget-sensitive designs or for heavy-duty applications where simplicity is valued, U-joints might be the better choice.

5. Maintenance expectations: If low maintenance is a priority, U-joints may be more suitable due to their simpler design and easier serviceability.

6. Operating conditions: For vehicles that frequently operate at extreme angles or in harsh environments, the choice may depend on the specific demands of the application.

Future Trends and Innovations.

As automotive technology continues to evolve, so do the designs of U-joints and CV joints. Some emerging trends include:

1. Advanced materials: Development of more durable and lightweight materials for both types of joints to improve performance and efficiency.

2. Hybrid designs: Some manufacturers are exploring hybrid joint designs that combine the strengths of both U-joints and CV joints.

3. Smart joints: Integration of sensors and smart materials to monitor joint health and performance in real-time.

4. Improved sealing technologies: Enhancing the longevity of CV joints by developing more effective and durable boot designs.

5. Optimization for electric vehicles: As electric vehicles become more prevalent, joint designs are being optimized for the unique torque characteristics of electric motors.

Universal Joints vs. Constant Velocity (CV) Joints – A Comprehensive Comparison Conclusion.

Both universal joints and constant velocity joints play crucial roles in modern vehicle drivetrains, each with its own set of advantages and limitations. U-joints excel in simplicity, robustness, and cost-effectiveness, making them ideal for certain heavy-duty applications and traditional drivetrain layouts.

CV joints, on the other hand, offer superior smooth operation and constant velocity transmission, making them indispensable in front-wheel-drive vehicles and applications requiring smooth power transfer at varying angles.

The choice between these two joint types ultimately depends on the specific requirements of the vehicle design, including factors such as drivetrain layout, suspension design, performance needs, and cost considerations.

As automotive technology continues to advance, we can expect to see further innovations in both U-joint and CV joint designs, potentially blurring the lines between these two historically distinct components.

Understanding the characteristics, advantages, and limitations of both U-joints and CV joints is crucial for automotive engineers, mechanics, and enthusiasts alike.

This knowledge not only aids in making informed decisions about vehicle design and maintenance but also deepens our appreciation for the intricate engineering that goes into every aspect of modern vehicles.

As we look to the future of automotive engineering, it’s clear that both U-joints and CV joints will continue to play important roles, evolving to meet the changing demands of vehicle performance, efficiency, and sustainability.

Whether it’s the tried-and-true simplicity of a U-joint or the smooth, constant velocity of a CV joint, these components will remain essential in connecting power to motion in the vehicles of tomorrow.

For our range of couplings from the worlds largest manufacturers,

go to our search engine to find the right uni joint or CV joint for you.

Citations:

[1] https://www.machter.com.au/blog/cv-joints-vs-universal-joints/.

[2] https://www.rctech.net/forum/nitro-off-road/829528-cvds-vs-universals.html.

[3] https://www.rzrforums.net/threads/cv-style-vs-u-joint-style-driveshafts-pros-and-cons.557904/.

[4] https://www.reddit.com/r/AskMechanics/comments/xuo5wr/why_are_universal_joints_used_on_driveshafts/.

[5] https://www.youtube.com/watch?v=WH8WjJ_ljjY.

[6] https://www.gt40s.com/threads/half-shafts-with-u-joints-vs-cv-joints.24205/.

[7] https://www.jeepforum.com/threads/cv-joints-vs-u-joints-on-front-axles.1368403/.

[8] https://www.physicsforums.com/threads/constant-velocity-joints-vs-universal-joint.652486/.