The Importance of Regular Maintenance for Tractor U-Joints

Table of Contents

Introduction

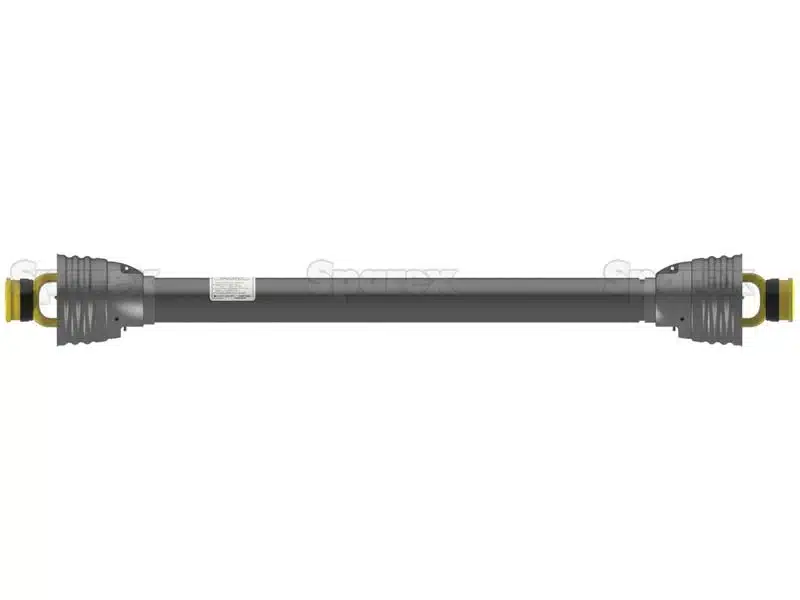

In agriculture, tractors work tirelessly under heavy loads, traversing rugged terrain and often facing challenging environmental conditions. At the heart of a tractor’s power transmission system are its U-joints, or universal joints, which are essential for connecting the driveshaft to the transmission and axles. U-joints enable the driveshaft to rotate at flexible angles, allowing tractors to power through uneven fields while keeping the wheels turning.

Failing to maintain these U-joints can lead to expensive repairs and operational downtime, especially during peak farming seasons. This post will explore why maintaining tractor U-joints is crucial, how to identify signs of wear, and ways to prevent deterioration. We’ll also highlight recommended U-joint models from top OEMs, including Spicer, Neapco, GMB, Moog, Weasler, Bondioli, and Walterscheid, along with their popular part numbers for agricultural use.

1. What Are Tractor U-Joints, and Why Are They Important?

Tractor U-joints are crucial for power transfer within a tractor’s drivetrain. These components connect the driveshaft to the transmission and axle, allowing for the movement and rotation of the shaft at flexible angles. This flexibility is vital for agriculture, where tractors regularly encounter uneven ground and require a consistent flow of power to maintain stability and performance.

Different types of U-joints are available for tractors, each offering unique features suited for specific applications. For example, cross-and-roller bearing U-joints provide high durability and are well-suited for heavy-duty tasks, while sealed U-joints require less maintenance due to their pre-lubricated design.

Leading OEM U-Joint Options:

Each brand offers models specifically designed to withstand the high-torque, high-stress conditions in agriculture:

- Spicer U-Joints: Known for durability, Spicer models like the 5-153X and 5-1310X are ideal for tractors used in high-torque applications, providing exceptional strength for handling heavy loads.

- Neapco U-Joints: Popular Neapco models, such as the 1-0173 and 3-7166X, are precision-engineered for durability, with a focus on vibration resistance, making them suitable for rough agricultural terrain.

- GMB U-Joints: With models like the 220-0150 and 240-0350, GMB provides heavy-duty U-joints for agricultural machinery exposed to harsh conditions.

- Moog U-Joints: Models such as the Moog 369 and Moog 393 are known for their longevity and smooth operation, making them a great choice for agricultural tasks.

- Weasler U-Joints: Weasler provides highly durable models like the 44-Series and 55-Series, which are widely used in agricultural PTO (power take-off) applications, valued for their robustness and longevity.

- Bondioli U-Joints: Bondioli’s 3200 Series and 5400 Series U-joints are popular in the agriculture industry, designed specifically for PTO and high-load applications.

- Walterscheid U-Joints: Known for innovation and quality, Walterscheid models like the W2300 and W2400 series U-joints are highly regarded for their resilience and reliability in high-stress, agricultural applications.

By selecting quality U-joints from trusted OEMs, tractor operators can ensure greater longevity and consistent performance, which is essential for maintaining an efficient agricultural operation.

2. Recognizing Signs of U-Joint Wear in Tractors

Understanding the signs of wear in U-joints can help prevent more significant issues and costly repairs. Regular inspections can catch early signs of wear, allowing for timely maintenance or replacement. Here are some common indicators that your tractor’s U-joints may need attention:

- Clunking or Clicking Noises: When shifting gears or engaging the driveshaft, clunking sounds may indicate worn bearings or loose U-joints, especially in high-torque environments.

- Vibrations While Operating: Excessive vibrations often stem from misaligned U-joints or worn bearings. These vibrations disrupt smooth power transfer, potentially damaging the entire drivetrain over time.

- Excessive Play or Movement in the Driveshaft: If there is noticeable looseness or play in the driveshaft, it may be due to a worn U-joint. A secure, tightly fitting U-joint is essential for optimal performance.

- Rust or Visible Wear on Bearings and Seals: External signs like rust or worn seals often indicate that the U-joint is not adequately protected from environmental elements, increasing the risk of damage.

Ignoring these signs can lead to damage beyond the U-joint itself, affecting components such as the driveshaft and transmission. Regular inspections allow tractor owners to catch these issues early and extend the lifespan of their equipment.

3. Causes of U-Joint Deterioration in Agriculture

Several factors contribute to U-joint wear and deterioration in agricultural machinery. Understanding these factors can help operators take preventative measures and extend the lifespan of their U-joints.

- Exposure to Harsh Environmental Conditions: Tractors operate in muddy, wet, and dusty conditions, exposing U-joints to moisture, dirt, and debris. These elements can wear down U-joint seals, causing corrosion and damage over time.

- High Load and Torque Stress: Agricultural tasks often involve pulling heavy loads, placing extreme torque on U-joints. This constant pressure accelerates wear on the bearings and can lead to premature failure.

- Improper Angles and Misalignment: When U-joints are not aligned properly, the uneven stress on the joint accelerates wear. Maintaining proper alignment is crucial for balanced load distribution and durability.

- Lack of Regular Lubrication: Regular lubrication helps prevent metal-on-metal contact, minimizing friction and heat. Without sufficient lubrication, U-joints are prone to excessive wear and risk seizing up, causing immediate and severe damage.

Addressing these factors with preventive maintenance, such as regular alignment checks and lubrication, helps reduce wear and ensures U-joints stay functional for longer.

4. The Role of Lubrication in U-Joint Maintenance

Lubrication is a fundamental part of U-joint maintenance, directly impacting its performance and lifespan. Proper lubrication reduces friction, prevents metal-on-metal wear, and protects U-joints from moisture and contaminants.

Recommended Steps for Lubricating Tractor U-Joints:

- Choose the Right Grease: High-temperature, water-resistant grease is ideal for agricultural U-joints. Products like Spicer Ultra-Premium Grease or Neapco Performance Grease are specifically formulated for high-load applications.

- Clean the Grease Fittings: Before applying grease, clean the fittings to remove dirt and debris, ensuring that contaminants don’t enter the joint.

- Apply Grease Thoroughly: Use a grease gun to apply lubrication until the old grease is expelled, indicating complete coverage of the bearings.

- Perform Regular Checks: Lubricate U-joints after heavy use or exposure to moisture, and always follow OEM guidelines for lubrication frequency.

Regular lubrication, particularly after periods of intense use, ensures that U-joints maintain optimal performance and prevents premature failure.

5. Step-by-Step U-Joint Maintenance Checklist for Tractors

A structured maintenance checklist helps ensure that U-joints receive consistent care, extending their life and reducing the risk of failure.

Daily and Weekly Inspections:

- Check for Noise and Vibration: Listen for unusual sounds and feel for any abnormal vibrations during operation, indicating early signs of wear.

- Visual Inspection: Look for rust, damaged seals, or any visible wear on the U-joints and surrounding parts.

Monthly and Seasonal Maintenance:

- Lubrication: Apply grease to U-joints as recommended by the OEM, especially before high-demand periods.

- Alignment Checks: Confirm that the driveshaft is properly aligned to reduce strain on U-joints.

Replacement Criteria for Worn U-Joints:

- If excessive play or looseness is detected in the driveshaft, it may be time to replace the U-joint.

- Recommended replacement models include Spicer 5-153X, Moog 369, Weasler 55-Series, and Walterscheid W2300 for various heavy-duty applications.

Maintaining a regular schedule helps prevent sudden breakdowns, ensuring that U-joints remain functional throughout the year.

6. Popular OEMs for Tractor U-Joints and Recommended Part Numbers

Selecting quality U-joints from reputable OEMs is essential for performance and longevity in agricultural equipment.

- Spicer U-Joints: For durability, Spicer’s 5-1310X and 5-153X are well-suited for high-torque applications, making them ideal for heavy-load tractors.

- Neapco U-Joints: Neapco offers models like 1-0153 and 3-7166X, engineered to handle agricultural wear with precision and reduced vibration.

- GMB U-Joints: GMB’s 250-0150 and 240-0353 provide heavy-duty performance, with high resistance to harsh environments.

- Moog U-Joints: Known for durability, Moog models 369 and 393 offer smooth operation and longevity.

- Weasler U-Joints: With models such as the 44-Series and 55-Series, Weasler U-joints are commonly used in PTO applications and are valued for robustness.

- Bondioli U-Joints: Bondioli’s 3200 Series and 5400 Series are specifically designed for PTO applications, offering strength in high-load settings.

- Walterscheid U-Joints: Walterscheid’s W2300 and W2400 series U-joints are well-regarded for their durability and reliability in demanding agricultural environments.

By choosing high-quality U-joints from trusted OEMs, tractor owners can improve performance, reduce downtime, and ensure the longevity of their equipment.

7. Long-Term Benefits of Regular U-Joint Maintenance for Tractors

Regular maintenance of tractor U-joints provides several long-term benefits:

- Improved Tractor Performance and Fuel Efficiency: Well-maintained U-joints ensure smooth power transfer, reducing vibration and increasing fuel efficiency.

- Reduced Downtime and Repair Costs: Regular inspections prevent sudden breakdowns, lowering the risk of emergency repairs and downtime during critical work periods.

- Extended Equipment Lifespan: Proper care and timely replacement of U-joints extend the life of the drivetrain, protecting other components such as the driveshaft and transmission.

- Higher Resale Value: A well-documented maintenance history can increase the resale value of the tractor, making it a more appealing investment for potential buyers.

The Importance of Regular Maintenance for Tractor U-Joints

Ready to Upgrade Your Tractor U-Joints?

Keeping your tractor’s U-joints in top shape is key to reliable performance and a long-lasting drivetrain. If it’s time to replace your U-joints, consider high-quality options from trusted OEMs like Spicer, Neapco, GMB, Moog, Weasler, Bondioli, and Walterscheid. Visit twinspringcoupling.com to explore our selection of premium U-joints and keep your tractor operating at its best all season long.