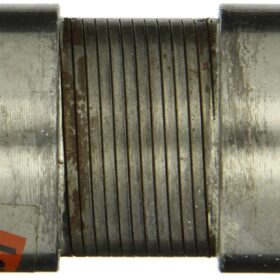

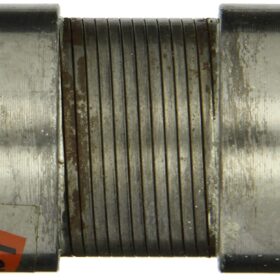

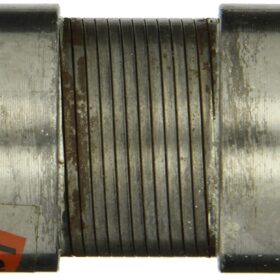

Ruland MOSC25-8-A Oldham Coupling Hub w Kw

| DIMENSIONS | |||

|---|---|---|---|

| Bore (B1) | 8 mm | Keyway (K) | 2 mm |

| Outer Diameter (OD) | 25.4 mm | B1 Max Shaft Penetration | 9.9 mm |

| Bore Tolerance | +0.03 mm / -0.00 mm | Hub Width (LH) | 9.91 mm |

| Length (L) | 28.6 mm | Recommended Shaft Tolerance | +0.000 mm / -0.013 mm |

| FASTENING HARDWARE | |||

| Forged Set Screw | M4 | Number of Screws | 2 ea 90° apart |

| Screw Material | Alloy Steel | Screw Finish | Black Oxide |

| Seating Torque | 2.2 Nm | Hex Wrench Size | 2.0 mm |

| PERFORMANCE SPECIFICATIONS | |||

| Torque Specifications | Torque ratings vary with insert selection | Angular Misalignment | 0.5° |

| Parallel Misalignment | 0.008 in (0.20 mm) | Max Parallel Misalignment | 0.100 in (2.54 mm) |

| Axial Motion | 0.004 in (0.10 mm) | Moment of Inertia | 1.2265 x 10-6 kg-m2 |

| Maximum Speed | 4,500 RPM | Recommended Inserts | OD16/25-AT, OD16/25-NL, OD16/25-PEK |

| Full Bearing Support Required? | Yes | Zero-Backlash? | Yes |

| Balanced Design | Yes | Mechanical Fuse? | Yes |

| ADDITIONAL INFORMATION | |||

| UPC | 634529128015 | Country of Origin | USA |

| Material Specification | 2024-T351 Aluminum Bar | Finish | Black Anodized |

| Finish Specification | Sulfuric Anodized MIL-A-8625 Type II, Class 2 and ASTM B580 Type B Black Anodize | Manufacturer | Ruland Manufacturing |

| Temperature | Acetal Disk -10°F to 150°F (-23°C to 65°) Nylon Disk -10°F to 130°F (-23°C to 54°C) PEEK Disk -10°F to 300°F (-23°C to 148°C) | Weight (lbs) | 0.029900 |

| Tariff Code | 8483.60.8000 | UNSPC | 31163015 |

Ruland MOSC25-8-A Oldham Coupling Hub w Kw

Ruland Oldham couplings are highly customizable, have a balanced design, and have low inertia.

While they can accommodate all forms of misalignment, they are especially useful in applications with parallel misalignment.

This Oldham coupling hub is manufactured from 2024 aluminum for lightweight and low inertia and has a BS 4235 standard keyway.

To make a complete coupling you must select two hubs and a disk insert.

Oldham couplings are highly customizable allowing the user to easily combine clamp or set screw hubs with inch, metric, keyed, and keyless bores.

The performance of the coupling is determined by the disk which is available in acetal for zero-backlash and high torque, nylon for dampening of impulse loads, and PEEK for high temperature.

Ruland manufactures Oldham couplings with a proprietary hub machining process that leaves a smoother surface for interaction between the hub and disk resulting in significantly longer life.

Oldham couplings have very low bearing loads protecting sensitive equipment and components from premature failure.

Ruland Oldham couplings are carefully made from select bar stock sourced exclusively from North American mills and are machined to a fine burr-free finish.

Hardware tests beyond DIN 912 12.9 standards for maximum torqueing capabilities.

Ruland, founded in 1937, manufactures all products in our Marlborough, MA USA factory under strict controls using proprietary processes.

Oldham couplings are RoHS2 and REACH compliant.