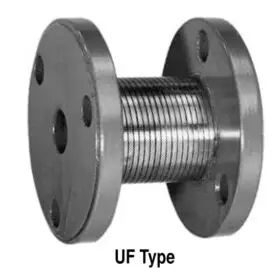

Martin F7SH Martin-Flex Coupling Flange Assembly

This Martin flex-coupling flange assembly transmits torque from one shaft to another when the two shafts are slightly misaligned.

It accommodates up to 4 degrees of angular misalignment, 1/8″ parallel misalignment, and 5/16″ end float.

It is made of high carbon steel for tensile strength and hardness, with an elastomeric tire element for absorbing shock and torsional vibration.

It is a two-piece flange for quick and easy installation, and the rubber element is fused to the metal hubs to prevent failure due to radial and axial load.

This flex-coupling flange assembly is suitable for use with electric motors, steam turbines, internal combustion engines, and reciprocating compressors, among others.

Roller chain sprockets are circular gear elements with deep, uniformly spaced teeth ringing the circumference of the gear.

The distance from the peak of one tooth to the next is called the pitch, and is commonly measured in 1/8″ increments. In the center of the sprocket is the bore (hole) which, depending on the sprocket’s design and application, might be augmented by a bushing or a bearing through which it is fixed to a shaft.

The sprocket transfers power and motion by a roller chain that is threaded over the teeth of the sprocket.

The chain links align with the sprocket’s pitch and at a length that prevents the chain from skipping, slipping, or binding.

Mounting space varies in application and generally determines the type of hub—a protruding, raised lip encircling the bore—a sprocket has.

A hub on either side of the sprocket is a Type C hub, a hub on one side of the sprocket is a Type B hub, and a no hub on either side is a Type A hub.

Some applications may require a sprocket to be swapped onto a shaft of a different diameter.

To make this swapping easier, designs have evolved where a sprocket might have a bore of a particular uniform size, and then bushings that have an outside diameter matching the bore of the sprocket but have varying inside bore diameters to accommodate different sized shafts can be swapped in as needed.

Roller chain sprockets are used in a broad range of applications where the drive power of an engine needs to be transferred into motion, such as in motor vehicles, conveyors, escalators, agricultural, forestry and mining equipment, aeronautics, robotics and space exploration, among others.

Martin Sprocket & Gear manufactures power transmission products, material handling components, and industrial hand tools.

The company, founded in 1951 and headquartered in Arlington, TX, meets International Organization for Standardization (ISO) standard 9001:2008.