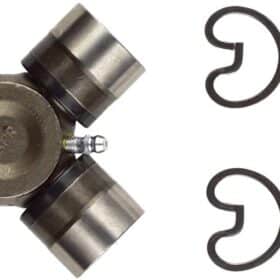

Lovejoy HD13 Heavy Duty Universal Joint Solid Bore

Lovejoy 68514424333 HD13 Heavy Duty Universal Joint, Solid Bore, 2.50″ Outer Diameter, 7.00″ Overall Length

Dimensional Data

Size | HD13 |

Set Screw Size | No Setscrew |

Outside Diameter | 2.500 in |

Overall Length | 7 in |

Bore Depth (Dimension C) | 2.000 in |

Max. Bore – No Keyway (Dim. ID1 & ID2) | 1.75 in44 mm |

Main Pin Height (Dimension E) | 3.5 in |

Cubic inches | 43.75 in³ |

Performance Data

Operating Temperature Range | -30 to 212 ºF |

Static Breaking Torque | 33120.00 in·lb |

Max. Speed | 1750.00 rpm |

Static Breaking Torque | 33120.00 in-lb |

Max. Angle Offset | 25.00 º |

Lovejoy HD13 Heavy Duty Universal Joint Solid Bore

This Lovejoy HD Type carbon steel single pin-and-block universal joint with solid hubs is designed to connect two rotating shafts at angles up to 25 degrees. Its induction hardened yoke ears provide longer life than our standard D Type joints.

This universal joint compensates for angular misalignments and has a single joint configuration for high torsional stiffness and torque capacity.

The hubs, center block, and pins are made of American Iron and Steel Institute (AISI) 1144 carbon steel for strength and durability, and the solid hubs have centering holes for custom machining.

Operating temperatures range from -30 to 212 degrees F. For optimal wear and extended life, boots (sold separately) are recommended, and boot retaining grooves are standard on this design.

This universal joint provides a uniform speed ratio between driving and driven shafts, and is suitable for applications requiring moderate torque transmission, such as compressors, fans, machine tools, printing presses, and textile machinery.

Universal joints (also called U-joints, universal couplings, Cardan joints, Hooke’s joints, or Hardy-Spicer joints) are used to transmit motion and rotational power, or torque, between two shafts that are offset at an angle.

Most universal joints consist of two yokes and a middle assembly; the hub end of each yoke attaches to a shaft while the yoke ears attach to and pivot around the middle assembly to accommodate shaft misalignment.

The type of middle assembly determines its usage—pin and block joints are suitable for transmitting high torque, needle bearing joints are used to handle high rotational speeds, and ball and socket joints are used in applications requiring low backlash (play between moving parts).

The body of the universal joint may include a single joint to accommodate only angular misalignments between shafts, or two joints to accommodate both angular and parallel misalignments.

Available in a variety of materials and configurations, universal joints are used in applications including motor vehicles, conveyors, medical and optical devices, forestry and mining equipment, robotics and space exploration, and aeronautics, among others.

Lovejoy manufactures flexible couplings, universal joints, variable speed drives, and other transmission and mechanical power products. The company, founded in 1900, is headquartered in Downers Grove, IL.