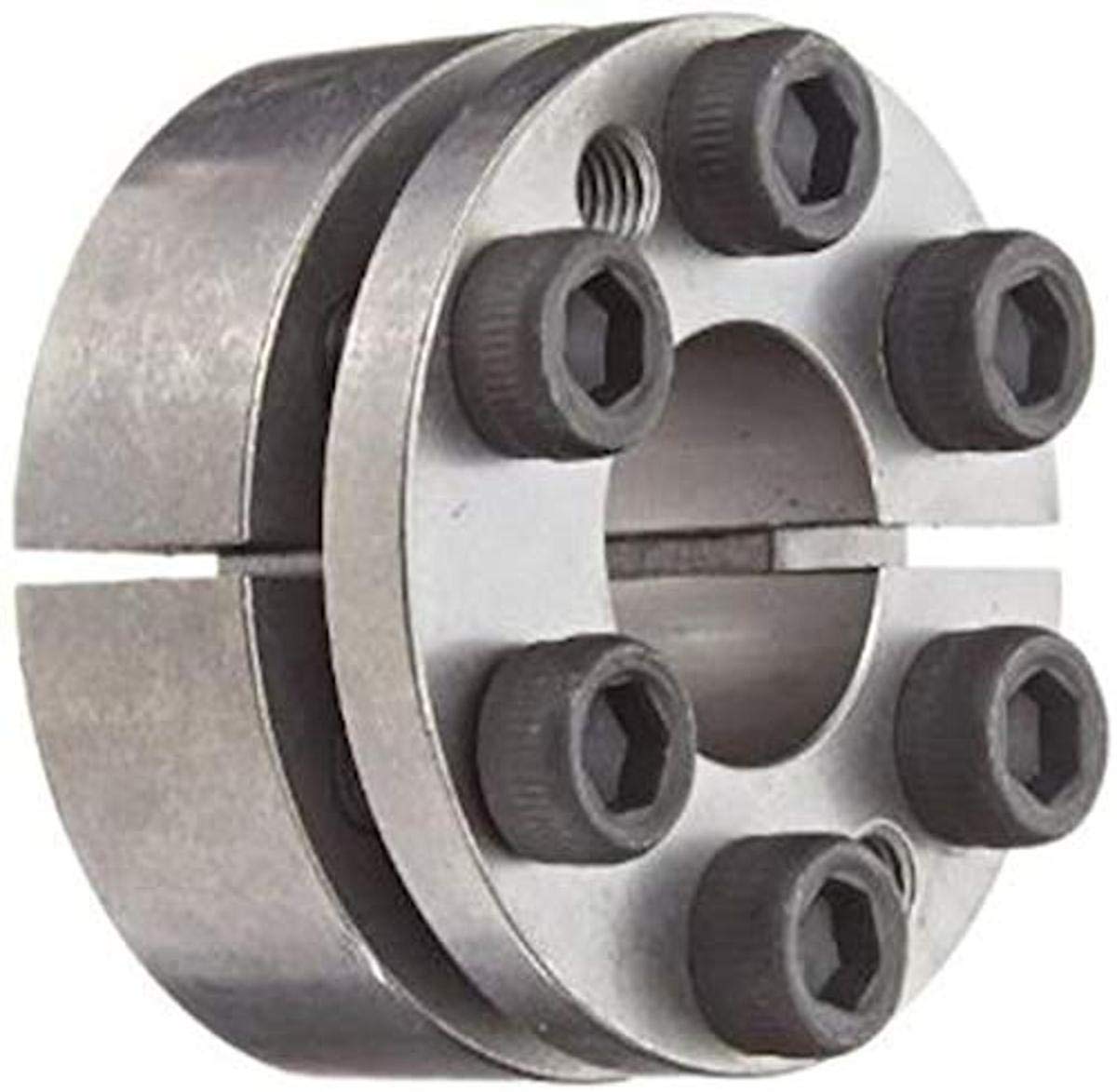

Lovejoy 1850 Series Shaft Locking Device 2-1/2 In shaft diameter

69790498181, SLD 1850 Series – Inch (Imperial)

Dimensional Data

Shaft Size | 2 1/2 in |

Hub Outside Diameter (Dimension d) | 2.500 in63.50 mm |

Tolerance of Shaft (T1) | +0 -0.0018 in |

Shaft Locking Device Outside Diameter (Dimension D) | 3.74 in95 mm |

Tolerance of Hub Bore (T2) | -0 +0.0022 in |

Thrust Rings Width at Relaxed State (Dimension B) | 1.319 in 33.50 mm |

Locking Screw Size (Dimension T) | M8 |

Contact Length (Dimension l) | 0.787 in 20.00 mm |

Total Width at Relaxed State (Dimension L) | 1.614 in 41.00 mm |

Cubic inches | 22.57599 in³ 573.43005 mm³ |

Performance Data

Max. Transmissible Axial Force | 23720.00 lbf |

Max. Transmissible Torque | 2471.00 ft·lb |

Screw Tightening Torque | 26.00 ft·lb |

Pressure on The Hub | 21176.00 psi |

Pressure on The Shaft | 23351.00 psi |

Features

Features | Versus Traditional Keyed Connections

Versus Traditional Interference Fits

Design Benefits

|

Lovejoy 1850 Series Shaft Locking Device 2-1/2 In shaft diameter

This Lovejoy SLD 1850 Series internal shaft locking device connects a hub to a shaft in power transmission applications.

Screw tension is converted into radial pressure to create an interference fit for zero backlash and high contact pressure for transmitting greater torque.

It is self-centering for even, concentric tightening.

It expands to fill the gap between shaft and hub for easy installation and removal, and the friction fit eliminates damage to the shaft caused by hub movement.

The axial hub can move during clamping for positioning the shaft.

This high-torque shaft locking device is suitable for use with compressors, conveyors, flywheels, gearboxes, reducers, and mixer shafts, among others.

Shaft collars are ring-shaped devices primarily used to secure components onto shafts. They also serve as locators, mechanical stops, and spacers between other components.

The two basic types of shaft collars are clamping (or split) collars, which come in one- or two-piece designs, and setscrew collars. In both types, one or more screws hold the collars in place on the shaft.

In setscrew collars, screws are tightened through the collar until they press directly against the shaft, and in clamping collars, screws are tightened to uniformly compress the collar around the shaft without impinging or marring it.

Whereas setscrew collars and one-piece clamping collars must be installed by sliding the collar over the end of the shaft, two-piece clamping collars separate into two halves and can be installed between components on the shaft.

Shaft collars are made from a wide range of materials including zinc-plated steel, aluminum, nylon, and neoprene.

Found in nearly every type of machinery and industry, shaft collars are used in applications including gearbox assemblies, motor bases, machine tools, drive shafts, agricultural implements, medical equipment, and paper and steel mill equipment.

Lovejoy manufactures flexible couplings, universal joints, variable speed drives, and other transmission and mechanical power products.

The company, founded in 1900, is headquartered in Downers Grove, IL.

Lovejoy 1850 Series Shaft Locking Device 2-1/2 In shaft diameter