Choosing the Right Industrial Coupling – A Comprehensive Guide to Leading Manufacturers for 2025

Table of Contents

Introduction

Power transmission reliability forms the backbone of industrial and mining operations. Whether managing conveyor systems, processing equipment, or heavy machinery, selecting the appropriate coupling directly impacts your equipment’s performance and longevity. This guide examines the leading coupling manufacturers and their specialized solutions for demanding industrial applications.

Major Manufacturers and Their Flagship Products

Lovejoy Coupling Solutions

Lovejoy has established itself as an industry leader with their precision-engineered coupling solutions. Their product line includes:

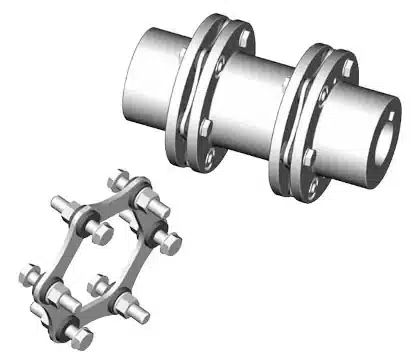

The Lovejoy Torsional Disc Coupling Series excels in high-speed applications where precision is paramount. These couplings offer:

- Zero maintenance design with no lubrication requirements

- High-speed capability up to 15,000 RPM

- Excellent for turbomachinery and precision equipment

- Advanced torsional stiffness characteristics

Their grid coupling line features the following advantages:

- Exceptional shock load absorption

- Cost-effective maintenance through replaceable components

- Proven reliability in demanding applications

- Superior vibration damping properties

Falk Corporation

Falk’s Steelflex Grid Coupling series represents decades of engineering excellence in power transmission. Their notable products include:

- Ideal for heavy industrial applications

- Outstanding shock load capacity

- Proven reliability in mining operations

- Excellent misalignment tolerance

Steelflex T20 Series:

- Enhanced torque capacity for demanding applications

- Robust design for harsh environments

- Superior performance in high-vibration settings

- Extended service life through optimized grid design

Rexnord Power Transmission

Rexnord’s Thomas Coupling series sets industry standards for precision applications:

Thomas Series 71:

- Engineered for high-speed operations

- Premium performance in critical applications

- Advanced disc pack design

- Superior balance characteristics

Thomas Series 52:

- General purpose applications

- Reliable performance in standard speed ranges

- Cost-effective solution for routine operations

- Simplified maintenance requirements

KopFlex Coupling Systems

KopFlex specializes in engineered coupling solutions for critical applications:

Their disc coupling line features:

- Advanced metallurgy for enhanced durability

- Precision-engineered components

- Superior balance characteristics

- Extended service intervals

Their grid coupling solutions provide:

- Robust construction for demanding applications

- Enhanced shock load capability

- Reliable operation in harsh environments

- Cost-effective maintenance options

TB Woods Power Transmission

TB Woods offers versatile coupling solutions for various industrial applications:

- Proven reliability in general industrial applications

- Excellent shock absorption characteristics

- Simplified maintenance procedures

- Cost-effective operation

Sure-Flex Elastomeric Couplings:

- Ideal for light to medium-duty applications

- Superior vibration damping

- No lubrication required

- Extended service life

Application-Specific Selection Guide

Mining Operations

Underground Mining Equipment:

- Continuous Miners: Falk Steelflex T35 or Lovejoy Grid Series

- Shuttle Cars: TB Woods Form-Flex or Falk T10

- Conveyor Systems: Falk Steelflex or Lovejoy Grid Series

Surface Mining:

- Crushing Equipment: Rexnord Thomas 71 or Falk T50

- Processing Plants: KopFlex Disc Series or Lovejoy Disc Series

- Material Handling: TB Woods Form-Flex or Falk Steelflex

Industrial Processing

Cement Production:

- Ball Mills: Falk Steelflex T50

- Crushers: Rexnord Thomas 82

- Conveyors: TB Woods Form-Flex or Lovejoy Grid Series

Steel Manufacturing:

- Rolling Mills: Falk Steelflex T35

- Processing Lines: Rexnord Thomas 71

- Auxiliary Equipment: TB Woods Form-Flex

Technical Specifications

Disc Coupling Specifications

Lovejoy Disc Series:

- Torque Range: 500 to 850,000 lb-in

- Speed Range: Up to 15,000 RPM

- Operating Temperature: -40°F to 350°F

Rexnord Thomas Series:

- Torque Range: 680 to 1,000,000 lb-in

- Speed Range: Up to 20,000 RPM

- Temperature Range: -40°F to 400°F

Grid Coupling Specifications

Falk Steelflex:

- Torque Range: 1,480 to 8,750,000 lb-in

- Speed Range: Up to 6,000 RPM

- Temperature Range: -30°F to 200°F

TB Woods Form-Flex:

- Torque Range: 1,200 to 7,500,000 lb-in

- Speed Range: Up to 4,500 RPM

- Temperature Range: -20°F to 180°F

Maintenance Guidelines

Disc Coupling Maintenance

Inspection Requirements:

- Visual inspection every 6,000 operating hours

- Torque verification of fasteners

- Alignment checks

- Disc pack condition assessment

Replacement Components:

- Disc packs

- Hardware sets

- Hub assemblies

Grid Coupling Maintenance

Service Intervals:

- Standard conditions: 6-month lubrication schedule

- Severe conditions: 3-month lubrication schedule

Recommended Lubricants:

- Falk LTG (Long Term Grease)

- Premium lithium-based grease

- Manufacturer-approved alternatives

Replacement Parts:

- Grid elements

- Seals and gaskets

- Cover assemblies

Selection Considerations

When choosing between coupling types, evaluate:

Performance Requirements:

- Operating speed

- Torque requirements

- Shock load conditions

- Misalignment needs

Environmental Factors:

- Operating temperature

- Exposure to contaminants

- Space constraints

- Accessibility for maintenance

Economic Considerations:

- Initial investment

- Maintenance costs

- Replacement part availability

- Expected service life

Choosing the Right Industrial Coupling – A Comprehensive Guide to Leading Manufacturers for 2025Conclusion

Selecting the right coupling involves careful consideration of operational requirements, environmental conditions, and maintenance capabilities. The manufacturers discussed here offer proven solutions for various industrial applications. For specific recommendations and detailed product information, consult with authorized distributors who can provide application-specific guidance based on your exact requirements.

Ready to Optimize Your Power Transmission System?

At Twin Spring Coupling, we understand that every industrial application presents unique challenges. Our team of power transmission specialists brings decades of combined experience in coupling selection and application engineering. We offer:

Expert Consultation

Our technical team provides personalized recommendations based on your specific operating conditions, maintenance capabilities, and performance requirements. We’ll help you navigate the selection process to find the perfect solution for your application.

Comprehensive Support

– Detailed technical specifications

– Installation guidelines

– Maintenance recommendations

– Troubleshooting assistance

– Emergency support when you need it most

Quality Assurance

Every coupling we supply comes with:

– Full manufacturer warranty

– Certification documentation

– Quality inspection reports

– Installation verification support

Take the Next Step

Contact our power transmission specialists today:

📞 718 938 1950

✉️ [email protected]

🌐 www.twinspringcoupling.com

Don’t let coupling selection uncertainty impact your operations. Reach out now for a free consultation and discover how our expertise can help maximize your equipment’s reliability and performance.

Remember: The right coupling choice today means reliable operation tomorrow. Let’s work together to find your optimal power transmission solution.